Just sharing because it got me stuck.

I use a 3D printer as a hobby, but recently it has been acting up… Apparently, the reason was that the extruder ribbon cable was not properly fastened to the stopper.

It’s a stupid thing once you understand it, but I struggled in my own way until I found the cause, so I’d like to share the process with you.

What happen

The 3D printer is a QiDi Tech iMateS model, which was purchased in October 2021. It has a pretty high uptime and on average prints about four days a week.

http://curo5170.s1008.xrea.com/x/20221119_post-587/

So, for the past year or so, printing has been failing more often.

The most common phenomenon is that the edges float like this.

I can tolerate it a little, but this is a rail guide, so I can’t use it if it’s distorted.

If you think that the rails are not settled properly, you can try to use rafts or brims, but sometimes it doesn’t work, and if you use rafts, the distortion will be within the range of the rafts, so rafts are often used as a good luck charm.

In the worst cases, the build sheet could be ejected from the printer and fall to the floor when you wake up in the morning.

It’s hard when this happens, there is a mass of PLA around the extruder and the inside of the printer is also full of rubbish.

Various analyses show trends.

①印刷中にフチが剥がれる

↓

②The edges come off during printing.

↓

③A passing extruder catches and displaces the build plate.

↓

④●×▽◇

Build plate outer edge easily peels off

After a number of print runs, a tendency becomes apparent that, especially when printing with printed material in the area at the back left, the prints are prone to fail / even if they do not go to failure, the distortion of the finished product increases, starting from the peeling in the area at the back left.

Although the back left is particularly bad, other outer edges also seem to be prone to flaking.

So, when I selected the modelling data and tried to print around the middle and a little forward of the middle as much as possible, I was able to print stably for a while.

Buy build plate.

But I can’t keep doing that.

At that time, we were making large quantities of items made of small parts, so we were able to adjust by reducing the amount of printing at a time, but naturally there are times when we want to make larger items.

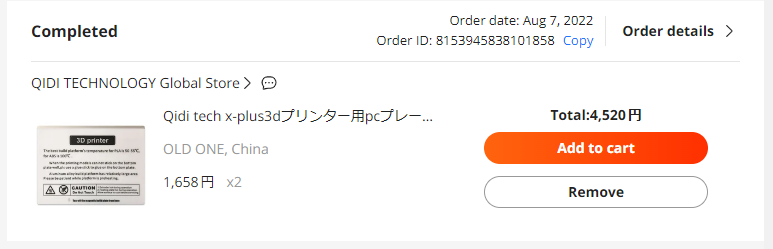

The build plate was also starting to hurt (it’s PLA, but why was it left with lines and stuff that had eaten into it to the point where it wouldn’t peel off?) So I bought the build plate, thinking that the bad bite was probably due to the build plate.

It says it is for the X-plus, but as the iMateS was supposed to be a cheaper version of the x-plus, we presume that the build plate was used from the x-plus. Comparing what we received, it is probably the same as the one that came with the iMateS from the beginning.

This improved the situation, but this was a misunderstanding.

The phenomenon still recurs, or rather fails a little bit.

(On second thoughts, the wear and tear of the build plate had nothing to do with it, as the peel is more likely to peel in areas that are not used very often…)

I thought there was a problem with the heater function of the heat bed (the table to which the build plate is attached) and that some parts of it were cold… I preheated it and checked things out, but the temperature was generally even, and there was no particular area that was cooler.

Cracks in the solder?

One day, I was disassembling and cleaning the jammed extruder as usual, and then re-loading it onto the head and trying to put filament into it, when I realised.

現在ノズル温度・・・1077度!?

This is strange. There should not be that much heating capacity.

If this is the case, the temperature sensor is faulty.

So the extruder must have been bad, because it was cured when I replaced the extruder with a spare one. I thought that the extruder was bad.

But recurrence.

However, they start to relapse when they forget.

(続く)

http://curo5170.s1008.xrea.com/x/20240223_post-1690/